The traditional glass printing process is mainly done by screen printing, water transfer printing, or hot stamping. Complicated process requiring high cost heavy equipment, making small amount production almost impracticable. Those cons have pushed inkjet technology rapidly in this industry. The application of digital printing in the glass industry focuses on decoration such as architecture, interior design, home decoration, automotive, transportation, etc. With the development of ink and glass materials, digital glass printing can create rich, durable and Functional design, which is impossible with other technologies.

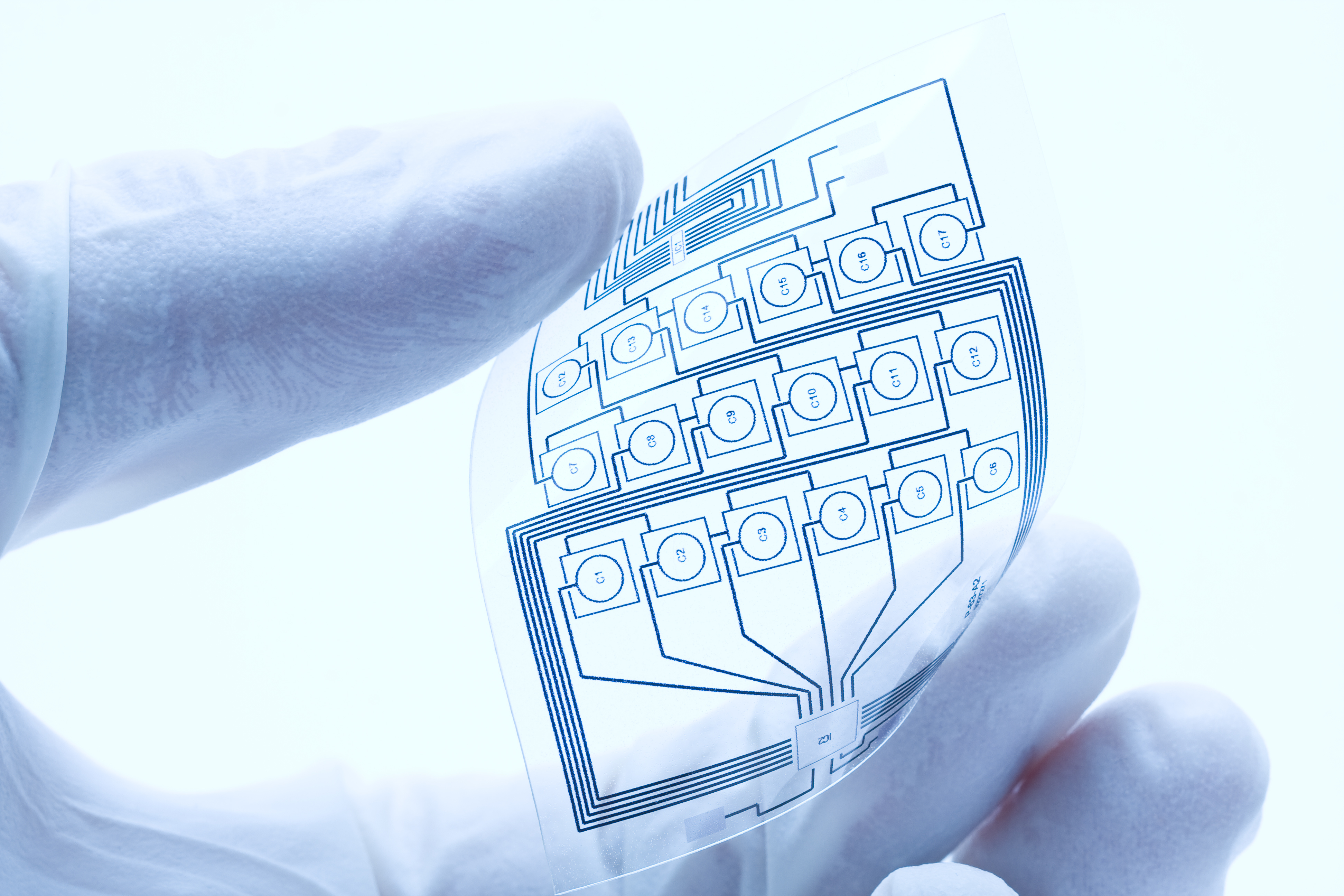

In the new century, electronic products are required to be light, thin, and strong to prevent breakage, and other characteristics. Those micro-electronic products require novel printed design, low cost and eco-friendly printing process. Printed electronics has been developed so far, in addition to conventional applications of RFID, conductive heat sheets, sensors, and forthcoming.

Production or unique applications such as liquid crystal displays (LCD), thin film transistors (TFT), organic cold light (EL) displays, lighting devices, solar cells, electromagnetic wave masking devices, circuit wiring boards, memory, or smart device antennas…

As a high-end fashion product, leather items have more varieties of popular colors and different flower shapes. The traditional leather coloring method is screen printing, but it is not suitable for use in progressive patterns, and it is necessary to produce the same number of color plates according to the color number, which is extremely cumbersome in the process, and it is very difficult for small amount order in recent years. UV digital printing offers better colors and precision. It can print colorful and multi-variable patterns, and the possibility to quickly bring changes of the same pattern, without repeating the starting process.

Traditionally, tile decoration is mostly made by screen printing, heavy equipment with ceramic ink and very high temperature heater. Big disadvantage of high installation cost, long production time and inconsistent production quality. With the increasing demand for custom designs, the tile printers that can print small quantities of products without opening the plate are becoming more popular. UV tile printing can shorten the process and reduce the energy. High image resolution and flexibility allow the tile design to be varied.

.jpg)

The gift market materials are diverse, the styles are small and varied, emphasizing the uniqueness and customary requirements. Digital printing does not require plate making and rapid printing. It has become a niche for gift makers. UV inks have good anti-friction properties and can be directly printed on a variety of materials. Through multi-layers printing method, you can create different special effects.

With the increasing number of on-demand printing request, and the fact that you do not need to hoard products in a warehouse, digital printing has become the best choice for gift manufacturers.