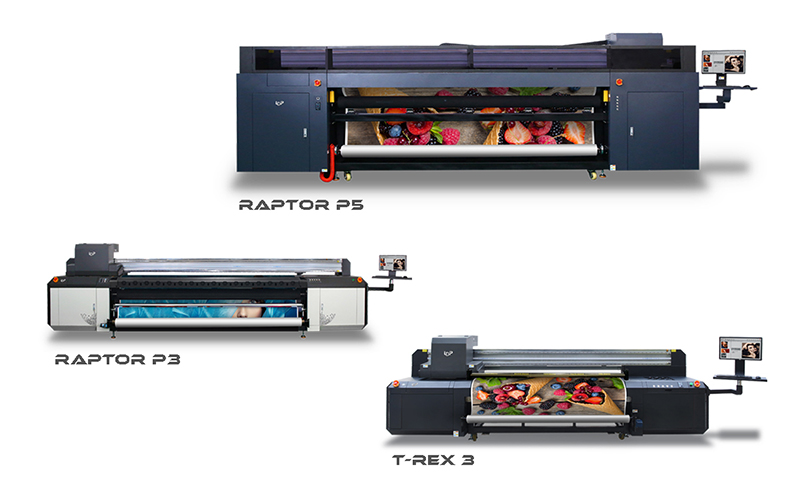

SERIES LINEUP

-

Selection of driving system

LDP provide different driving control systems and equipment sizes to meet different markets requirements.

-

Suitable for heat-sensitive and elastic materials. Smooth printing without wrinkles and wider range of printing applications.

-

The carriage is equipped with anti-static and anti-collision devices to effectively protect the print head and stabilize the printing quality.

-

-

Tension Control Series-RAPTOR 2

Stable and uniform driving force: rubber rolls to precisely drive consumables. Media tension is uniform, surface is smooth, even with soft materials.

-

The rubber tension rolls are used to drive the material with a constant tension, avoiding problems of wrinkles or twist faced with extremely soft consumables during the printing process.

-

According to material characteristics (flexibility, elasticity, …) but also applications (outdoor/indoor), or even production cost, LDP propose selection of different kinds of ink to match your requirements.

-

-

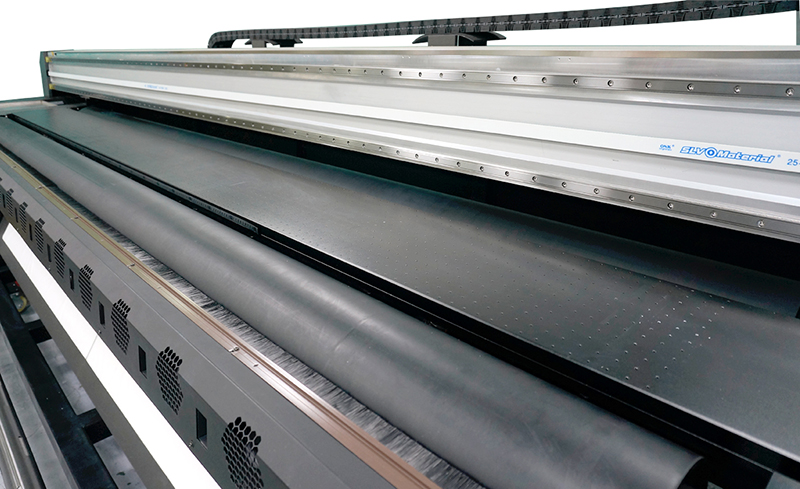

Conveyor belt system –T-REX 3

The potential of this hybrid printer combining rolls and plate is endless: wide printing platform combined with roll rewinding system, both soft and hard substrates can be easily printed.

- Can print multiple small plates, signboards or standing cards in one time.

- Teflon belt: no electrostatic interference during printing process.

- Large image output can be easily printed on large sheets, without need to readjust their position, reducing tiring process. Faster production efficiency, and lower waste.

-

Diversified printing modes

Select the right print mode for all kinds of advertising prints to reach the most accurate result with realistic colours.

-

Each GUV series equipment is equipped with an integrated light box to check the printing quality.

-

Bright six-color ink to reach realistic skin ton. High-masking white ink to get true colors even on colored materials.

-